Efficient Selector Solenoid: A Game-Changer in Modern Technology

By:Admin

Introduction:

In today's rapidly advancing industrial automation landscape, one company is leading the charge with its groundbreaking technology and expertise. This company, which specializes in the design and development of high-quality industrial components, has recently unveiled its latest marvel - the cutting-edge Selector Solenoid.

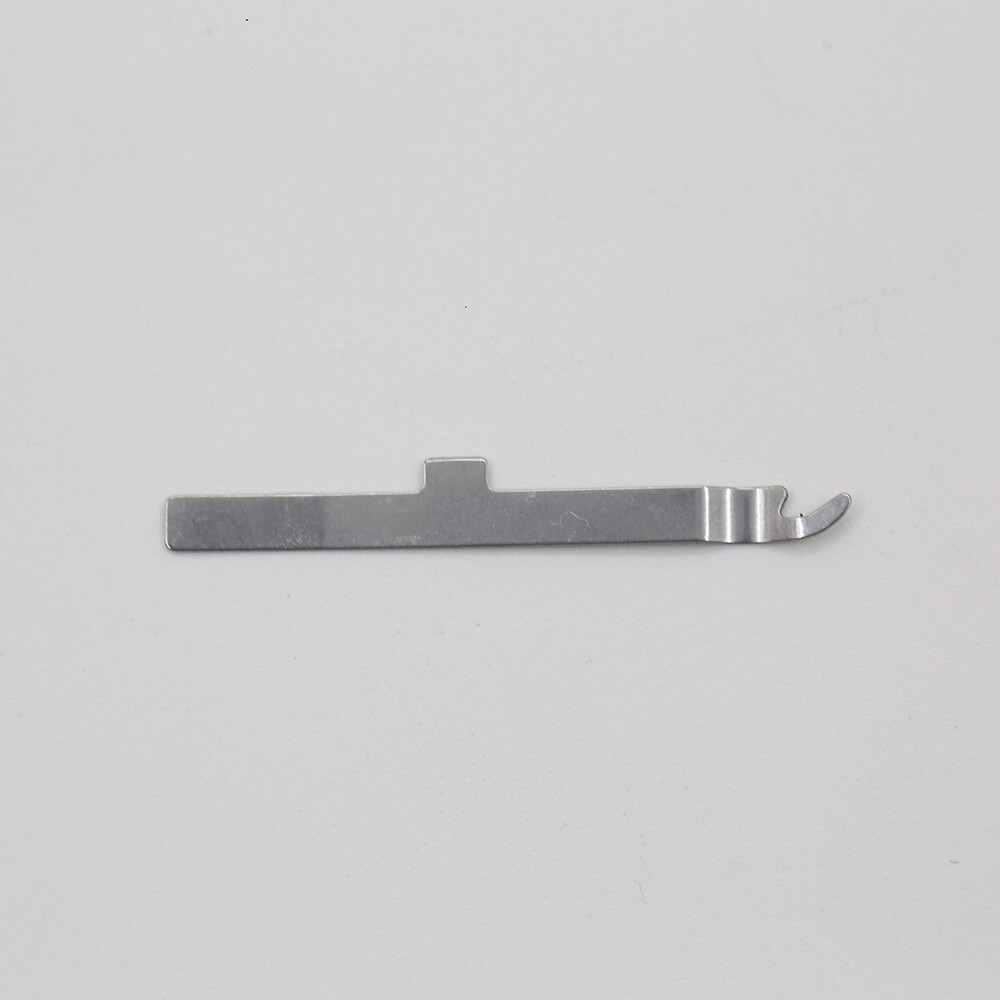

Selector Solenoid: Redefining Efficiency and Precision in Industrial Automation

The Selector Solenoid, developed by this renowned company, is set to revolutionize the field of industrial automation. With its innovative design and advanced features, this high-performance solenoid offers unparalleled efficiency, precision, and reliability, setting a new standard for the industry.

Efficiency and Power Optimization:

The Selector Solenoid is engineered to enhance efficiency and minimize energy consumption in industrial processes. By employing smart power optimization algorithms, it ensures optimal power usage, significantly reducing overall operating costs. This feature makes it an ideal solution for high-volume applications, such as assembly lines, production plants, and logistics facilities.

Advanced Actuation Technology:

Equipped with advanced actuation technology, the Selector Solenoid achieves lightning-fast response times, enabling rapid and precise movements. This technology allows for seamless integration into complex automated systems, improving overall productivity and operating efficiency. Furthermore, the solenoid's robust construction ensures a long lifespan and minimal maintenance requirements, making it a cost-effective choice for industries of all scales.

Flexibility and Customizability:

Recognizing the diverse needs of different industries, the Selector Solenoid offers versatile customization options. Companies can tailor the solenoid's specifications, such as voltage, force, and stroke length, to their specific requirements. This flexibility ensures that the solenoid seamlessly integrates into existing infrastructure while delivering optimal performance.

Reliability and Safety Assurance:

The Selector Solenoid prioritizes reliability and safety by incorporating fail-safe mechanisms and stringent quality control processes. Its design includes built-in protections against overheating and voltage fluctuations, ensuring consistent performance even under demanding conditions. The solenoid's compliance with industry safety standards guarantees the well-being of operators and minimizes the risk of accidents.

Industry Applications:

With its exceptional design and performance, the Selector Solenoid finds applications across various industries. In the automotive sector, it enables precise control of assembly line mechanisms, contributing to improved production quality and efficiency. In warehousing and logistics, the solenoid facilitates the smooth operation of material handling and sorting systems, reducing errors and optimizing throughput.

Furthermore, the Selector Solenoid proves invaluable in the pharmaceutical and medical sectors, where it contributes to the precise movement and positioning of delicate instruments in laboratory automation and medical diagnostics equipment. In these industries, the solenoid's reliability and precision are critical to ensuring accurate results and maintaining quality standards.

Partnerships and Collaborations:

To amplify the reach and impact of their groundbreaking Selector Solenoid, this company has strategically forged partnerships with industry-leading automation manufacturers and integrators. By fostering collaboration with these key players, the company aims to streamline the adoption and integration of their solenoid into a myriad of automation solutions, accelerating technological advancements in industrial automation.

Conclusion:

In the progressive world of industrial automation, the selector solenoid developed by this visionary company stands out as a game-changer. Its exceptional efficiency, precision, reliability, and customization options ensure seamless integration into diverse automation systems, benefiting industries across the board.

By harnessing the power of the Selector Solenoid, industries can unlock unparalleled productivity gains and operational excellence. With an unwavering commitment to innovation and customer-centric solutions, this company continues to shape the future of industrial automation, paving the way for a more efficient and advanced industrial landscape.

Company News & Blog

Qualities that Make Watch Movements Accurate and Reliable

When it comes to purchasing a watch, accuracy and reliability are two key factors that most people consider. The movement of a watch, whether mechanical or quartz, is responsible for its accuracy and reliability. Let's dive into what makes a watch movement accurate and reliable.Mechanical MovementsMechanical watches operate without the use of batteries or electronic components. Instead, they rely on a complex series of gears, springs, and other mechanical parts to keep time. One of the factors that make mechanical movements accurate is the use of a balance wheel. The balance wheel oscillates back and forth, and the speed of its oscillation determines the accuracy of the timekeeping.Additionally, mechanical movements are manually wound, which means that you have to wind the watch to keep it running. This creates a consistent and even energy flow to the balance wheel. However, mechanical watches can be affected by external factors such as gravity or temperature changes.Reliability is also important when it comes to mechanical watches. A well-maintained mechanical watch can last for generations. However, due to the complexity of the movement, a mechanical watch requires regular servicing to ensure that it operates correctly.Quartz MovementsQuartz watches use electronic components to keep time. The movement contains a small quartz crystal that vibrates at a specific frequency when a current is applied. The frequency is stable and constant, making quartz watches extremely accurate.Unlike mechanical watches, quartz movements rely on a battery to keep them running. The battery powers an electronic circuit that sends a pulse to the crystal, which in turn regulates the movement of the watch. Quartz watches are less affected by external factors such as temperature changes and can maintain accuracy over long periods of time.In terms of reliability, quartz watches are known for their durability and low maintenance requirements. They don't require regular servicing like mechanical watches, and the battery can be easily replaced when it runs out.Accuracy Movement WatchesWhen it comes to accuracy, both mechanical and quartz movements have their strengths and weaknesses. Mechanical watches offer a traditional feel and require more maintenance, but they can last for generations if cared for correctly. In contrast, quartz watches are extremely accurate and require minimal maintenance.However, advancements in technology have allowed watchmakers to combine the best of both worlds. There are now hybrid watches that use a combination of mechanical and quartz movements. These watches offer the traditional appeal of a mechanical watch with the accuracy of a quartz movement.To ensure that your watch is accurate and reliable, it's important to purchase from a reputable brand and take care of it properly. Regular servicing can help maintain accuracy and extend the lifespan of your timepiece.In conclusion, whether you prefer a mechanical watch or a quartz watch, accuracy and reliability are important factors to consider. The movement of the watch is responsible for its accuracy and reliability, and advancements in technology have allowed watchmakers to create hybrid watches that offer the best of both worlds. With proper care and maintenance, a watch can last for generations and remain a reliable timekeeping companion.

Making Bamboo Knitting Needles: A Step-By-Step Guide

As the demand for sustainable and eco-friendly products increases, more and more people are turning to bamboo knitting needles as an alternative to traditional metal or plastic needles. But how are these popular needles made?Bamboo knitting needles are made from the wood of the bamboo grass, which grows quickly and sustainably. Most bamboo knitting needles are produced in China, where bamboo is plentiful.The process of making bamboo knitting needles begins with the harvesting of mature bamboo stalks. The stalks are cut into sections and dried in the sun for several weeks until they are completely dry and free from moisture.Once the bamboo sections have been dried, they are cut into the desired length for knitting needles. The size and shape of the needles are determined by the specific needs of the knitting project. The needles are then sanded and smoothed to remove any rough edges or imperfections.The next step in the process is to create the knitting needle tips. This is done by heating the bamboo sections over a wood-burning stove until they are pliable. The heated bamboo is then bent into the desired shape and held in place until it cools and hardens.One of the unique qualities of bamboo needles is that they can be made in a variety of shapes and sizes, including straight, circular, and double-pointed needles. This versatility makes them a popular choice for knitters of all levels.After the needle tips are formed, they are joined to the needle shaft using a glue or adhesive. The needle tips and shaft are then sanded and polished to create a smooth finish.The final step in the production of bamboo knitting needles is to apply a protective coating to the needles to make them more durable and long-lasting. Some manufacturers may apply a wax coating, while others may use a water-resistant varnish.One company that specializes in the production of high-quality bamboo knitting needles is (Brand Name). Founded in (Year), (Brand Name) has been committed to creating sustainable knitting products using natural materials and responsible production methods.(Company introduction) (Brand Name) offers a wide range of bamboo knitting needles in various sizes, shapes, and styles. Their products are crafted by skilled artisans who take pride in creating beautiful and functional knitting tools that are gentle on the environment.In addition to bamboo knitting needles, (Brand Name) also offers a variety of other knitting accessories, including stitch markers, project bags, and needle cases. All of their products are made with the same dedication to quality and sustainability that has become synonymous with the (Brand Name) name.As more people become aware of the benefits of using sustainable products, the demand for bamboo knitting needles is sure to continue to grow. With their beautiful, natural aesthetic and eco-friendly construction, bamboo needles are the perfect choice for any environmentally-conscious knitter.

Solar-Powered Digital Thermometer for Refrigerant Equipment - China Manufacturer

In today's world, we rely heavily on technology to provide us with accurate and efficient measuring instruments. Thermometers play a significant role in maintaining the optimal temperature in our homes and workplaces. The DST-30 Solar-Cell Digital Thermometer is one such device that uses solar energy to provide us with accurate temperature readings. This thermometer is designed for use in refrigerant equipment, such as cabinets and display cases. It is equipped with a big LCD display that makes it easy to read temperature levels. The thermometer has a temperature range of -50 to 150 degrees Celsius, with a measuring range of -20 to 80 degrees Celsius. One of the most significant advantages of the DST-30 Solar-Cell Digital Thermometer is its accuracy. The device has a resolution of 0.1, meaning it can detect even the slightest temperature changes. This makes it an ideal choice for applications that require precise temperature monitoring. The thermometer is also waterproof, which makes it durable and long-lasting. It is built to withstand harsh environments and can operate in extreme temperatures, making it suitable for use in a variety of industries. The DST-30 Solar-Cell Digital Thermometer is an OEM product made in China. OEM products are custom-made according to the requirements of the buyer. This means that the buyer can customize the design of the thermometer according to their needs. This flexibility makes it a popular choice among businesses that require specialized equipment to suit their specific needs. In conclusion, the DST-30 Solar-Cell Digital Thermometer is an excellent investment for businesses that require accurate and efficient temperature monitoring. It is a reliable and durable device that can withstand harsh environments and extreme temperatures. Its flexibility allows it to be customized according to the buyer's needs. With its high accuracy and solar-powered energy source, the DST-30 Solar-Cell Digital Thermometer is an excellent addition to any workplace. Keywords: OEM, Measure, Instrument, Gear, Digital Thermometer, Solar energy, Accuracy, LCD display, Temperature range, Waterproof, Refrigerant equipment, Custom-made.

Solenoid Manufacturer Achieves Remarkable Developments in Seiki Shima Industry

[Company Introduction]Seiki Shima Solenoid GmbH is a leading provider of innovative solenoid solutions based in Germany. With over 50 years of experience in the industry, Seiki Shima Solenoid has established itself as a trusted name in the field of solenoid technology. The company prides itself on its commitment to quality, efficiency, and customer satisfaction.Seiki Shima Solenoid offers a wide range of solenoids for various applications, including automotive, industrial, medical, and consumer electronics. Their solenoids are known for their precision, reliability, and excellent performance, making them the preferred choice for a diverse range of customers worldwide.[News Content][Headline]: Solenoid Innovator, Seiki Shima Solenoid GmbH, Continues to Lead the Industry[Subheadline 1]: Unveiling a New Generation of High-Performance Solenoids[Date][CITY, COUNTRY] - Seiki Shima Solenoid GmbH, a global leader in solenoid technology, has once again pushed the boundaries of innovation with the introduction of its latest range of high-performance solenoids. Designed to meet the ever-increasing demands of various industries, these solenoids promise exceptional reliability and efficiency, setting a new industry benchmark.[Subheadline 2]: Advanced Engineering for Automotive ApplicationsSeiki Shima Solenoid has been at the forefront of providing solenoid solutions to the automotive sector for decades. Their dedication to developing cutting-edge products has earned them a reputation as a trusted partner for leading automotive manufacturers worldwide.The new generation of solenoids introduced by the company boasts enhanced functionality, making them ideal for next-generation vehicles that rely heavily on advanced electronic systems. These solenoids offer improved power efficiency, higher force generation, and increased durability, ensuring optimal performance even in the most challenging automotive environments.[Subheadline 3]: Revolutionizing Industrial Automation with Smart SolenoidsSeiki Shima Solenoid understands the importance of automation in industrial processes and is committed to developing solenoids that contribute to improved efficiency and productivity. The company's latest range of smart solenoids integrates advanced sensing and communication capabilities, enabling seamless integration with Industry 4.0 technologies.These intelligent solenoids monitor various parameters, such as temperature, pressure, and position, providing real-time feedback to optimize control systems. With their self-diagnosis and predictive maintenance capabilities, these solenoids help industrial manufacturers minimize downtime and maximize operational efficiency.[Subheadline 4]: Advancements in Medical and Consumer Electronics ApplicationsSeiki Shima Solenoid has extended its expertise to the medical and consumer electronics sectors, addressing their unique solenoid requirements. The company's solenoids for medical devices ensure precise and reliable actuation, essential for critical applications like drug delivery systems and surgical equipment.In the consumer electronics realm, Seiki Shima Solenoid offers solenoids for a variety of applications, including mobile phones, cameras, and audio devices. These solenoids provide haptic feedback, enhancing the user experience and enabling more immersive interactions with electronic devices.[Subheadline 5]: Commitment to Quality and Customer SatisfactionAt Seiki Shima Solenoid, quality is paramount. The company's solenoids undergo rigorous testing and quality control measures to ensure they meet the highest standards. By leveraging advanced manufacturing techniques and utilizing the latest materials, Seiki Shima Solenoid consistently delivers solenoids that surpass customer expectations.Moreover, the company's unwavering commitment to customer satisfaction differentiates it from competitors. Seiki Shima Solenoid is known for its responsive customer support, prompt delivery, and customized solutions tailored to meet specific customer requirements.[Closing Statement]Seiki Shima Solenoid GmbH continues to lead the solenoid industry through its relentless pursuit of innovation, dedication to quality, and commitment to customer success. As industries evolve and demand advanced solenoid solutions, Seiki Shima Solenoid remains a trusted partner, enabling the next generation of technological advancements.

Revolutionary Electric Weaving Machine Takes the Textile Industry by Storm

Title: Revolutionary Electric Weaving Machine set to Transform Textile Manufacturing IndustryIntroduction:In a groundbreaking development, an innovative new Electric Weaving Machine is set to revolutionize the textile manufacturing industry. Manufactured by an esteemed company known for its dedication to cutting-edge technology and quality products, this state-of-the-art machine promises unparalleled efficiency, productivity, and sustainability in the weaving process. With its advanced features and intelligent design, this machine is poised to redefine the future of textile manufacturing.Paragraph 1:The Electric Weaving Machine integrates the latest technological advancements, employing a combination of robotics, automation, and artificial intelligence. These features ensure optimum production capacity, rapid adaptation to changing production demands, and enhanced fabric quality. The machine has been meticulously developed to meet the needs of textile manufacturers and elevate the efficiency of the entire production process.Paragraph 2:This machine offers a range of exciting benefits when compared to traditional weaving machines. Firstly, its advanced automation reduces the reliance on human labor, resulting in improved production output and resource utilization. This not only enhances efficiency but also allows manufacturers to allocate their workforce to more skilled tasks, further improving overall productivity. Additionally, with its precise controls and integrated sensors, the machine minimizes material wastage, resulting in cost savings.Paragraph 3:The Electric Weaving Machine also prioritizes sustainability by significantly reducing energy consumption. Utilizing cutting-edge electrical systems and energy-efficient components, it minimizes environmental impact while producing high-quality textiles. Manufacturers can seamlessly transition to this machine, effectively lowering their carbon footprint and meeting their sustainability targets.Paragraph 4:Designed with user-friendliness in mind, this machine boasts a comprehensive control interface, allowing operators to easily monitor and adjust various parameters. Its intuitive software enables efficient pattern creation, ensuring manufacturers can effortlessly meet diverse customer demands. Furthermore, the machine's robust construction ensures durable performance, reducing downtime and maintenance costs.Paragraph 5:The Electric Weaving Machine's adaptability and flexibility are key features that set it apart from its conventional counterparts. Equipped with artificial intelligence algorithms, it quickly adapts to changing fabric specifications and production requirements. This adaptable nature enables manufacturers to swiftly respond to market demands, reducing time-to-market and enhancing their competitiveness.Paragraph 6:The Electric Weaving Machine not only excels in efficiency but also guarantees superior fabric quality. With its precise weaving mechanisms, it ensures consistency, evenness, and high tensile strength in the textiles produced. Manufacturers can proudly offer a higher-quality product, meeting the demands of discerning consumers in an increasingly competitive market.Paragraph 7:As global textile production continues to grow at an accelerated pace, investing in innovative technologies like the Electric Weaving Machine becomes crucial for manufacturers to stay ahead. The adoption of such advanced machines ensures enhanced productivity, reduced costs, improved sustainability, and a competitive edge in the industry.Conclusion:With its remarkable features and unwavering commitment to innovation, the Electric Weaving Machine is set to transform the textile manufacturing industry. By combining cutting-edge technology and efficiency-driven design, it offers manufacturers the opportunity to revolutionize their production processes, significantly improve fabric quality, and reduce environmental impact. As textile manufacturers seek new ways to meet rising demands while embracing sustainability, this electric weaving machine presents a groundbreaking solution.

Manufacturer offers a variety of Jacquard spare parts in Mumbai

Konica Electronics Enterprise: Leading the Way in the Manufacturing of Quality Jacquard Spare PartsKonica Electronics Enterprise is a Mumbai-based company that specializes in the production of Jacquard spare parts. The company has been in operation for many years and has garnered a reputation for being one of the best manufacturers of Jacquard spare parts in India. The company’s mission is to provide high-quality Jacquard spare parts that meet the exact needs of their customers.Jacquard spare parts are essential components in the weaving industry, and as such, they are in high demand all across the world. Jacquard looms are used to produce intricate designs in textiles that cannot be achieved by traditional weaving methods. However, to achieve this level of complexity, the looms require the use of Jacquard spare parts.Konica Electronics Enterprise produces a wide range of Jacquard spare parts, including the Staubli M5 Module, Staubli Jacquard M5 Module Outer Plate, Staubli Jacquard M4.m5 Pulley Upper Line, and Staubli Jacquard M4,m5 Bracket With Bearings. These spare parts are of high quality, durable, and are designed to meet the exact needs of their customers.The Staubli M5 Module is one of the most popular products produced by the company. It is a compact and versatile module that can be used in a wide range of weaving machines. The module is designed to be easy to use and maintain and is known for its exceptional performance and reliability.The Staubli Jacquard M5 Module Outer Plate is another essential product produced by Konica Electronics Enterprise. It is designed to fit perfectly with the Staubli M5 Module and is made from high-quality, durable materials. The outer plate is crucial for protecting the module from damage and ensuring that it functions correctly.The Staubli Jacquard M4.m5 Pulley Upper Line is another product that is highly sought after by customers. It is designed to be compatible with a wide range of weaving machines and is known for its exceptional performance and ease of use. The pulley upper line is used to control the movement of the heddles in the loom, making it an essential component in the weaving process.Lastly, the Staubli Jacquard M4,m5 Bracket With Bearings is another product that is highly valued by customers. It is designed to be durable and long-lasting and is used to hold the pulley in place. The bracket is made from high-quality materials, ensuring that it can withstand heavy usage.Konica Electronics Enterprise is known for its commitment to producing high-quality Jacquard spare parts. The company has invested heavily in modern technologies and machinery to ensure that their products meet the highest standards of quality and durability. They have a skilled and experienced team of professionals who are dedicated to delivering the best solutions to their customers.In conclusion, Konica Electronics Enterprise is a leading manufacturer of Jacquard spare parts in India. They have a wide range of products that are designed to meet the exact needs of their customers. Their commitment to quality, durability, and performance has earned them a reputation as one of the best Jacquard spare parts manufacturers in the country. If you are in need of high-quality Jacquard spare parts, then Konica Electronics Enterprise is the company to reach out to.

Revolutionary Fabric Loom Machine Unveiled - Enhancing Modern Weaving Techniques

[Title]Innovative Fabric Loom Machine Revolutionizes Textile Industry[Subtitle]Groundbreaking Technology Transforms Textile Production for Enhanced Efficiency and Quality[Date][City], [Country] – In a significant breakthrough for the textile industry, a revolutionary fabric loom machine has been unveiled, promising to transform the way fabrics are produced. Developed by an industry-leading company committed to innovation and efficiency, this cutting-edge technology is set to redefine textile manufacturing.[City], [Country] – [Company Name], a renowned textile machinery manufacturer with a track record of innovative solutions, has recently introduced its state-of-the-art fabric loom machine. This groundbreaking technology is poised to revolutionize the textile industry, offering enhanced production efficiency, improved quality, and increased customization capabilities.The fabric loom machine, which has been meticulously developed by the skilled engineers at [Company Name], offers a range of features that set it apart from traditional looms currently in use. With its advanced design and automation capabilities, this modern machine promises to streamline the fabric production process.One of the notable features of this cutting-edge fabric loom machine is its high-speed operation. Equipped with the latest technology, it enables rapid weaving, increasing production capacity while ensuring top-tier quality. Its advanced control system allows for precise and stable weaving, minimizing flaws and defects in the fabrics produced.Furthermore, this fabric loom machine introduces an unparalleled level of customization. The intuitive user interface provides textile manufacturers with extensive control over various weaving parameters, including patterns, colors, and fabric thickness. This greatly expands the possibilities for creating unique and tailored fabrics, meeting the diverse demands of designers and consumers alike.The fabric loom machine also boasts significant efficiency improvements over traditional loom technology. With its automated features, operators can complete tasks that previously required intensive manual labor. This not only reduces production time but also minimizes the risk of human errors, lowering costs and increasing overall productivity.In addition to its efficiency and customization capabilities, this fabric loom machine is also designed with sustainability in mind. It incorporates advanced energy-saving mechanisms, ensuring efficient use of resources. By reducing energy consumption and minimizing waste, this technology aligns with the growing emphasis on sustainability within the textile industry."The introduction of our fabric loom machine represents a major milestone for textile manufacturers," said [Company Name]'s spokesperson. "We believe this state-of-the-art technology will revolutionize the fabric production process, enabling our customers to achieve higher productivity, superior quality, and unmatched versatility."The fabric loom machine by [Company Name] has already garnered significant interest from key players in the textile industry. Several renowned manufacturers have expressed their enthusiasm for this innovative solution and are already considering integrating it into their production lines.As the textile industry continues to evolve, machinery manufacturers like [Company Name] play a crucial role in driving innovation and efficiency. By developing and delivering cutting-edge technologies, they empower textile manufacturers to stay ahead in a competitive market, meet changing consumer demands, and contribute to a more sustainable future.With its advanced features, including high-speed operation, customization capabilities, increased efficiency, and sustainability focus, the fabric loom machine by [Company Name] is set to transform the textile industry. As textile manufacturers embrace this revolutionary technology, the future of fabric production looks brighter than ever before.About [Company Name]:[Company Name] is a leading global textile machinery manufacturer renowned for its commitment to innovation and customer satisfaction. With a strong focus on research and development, the company strives to deliver state-of-the-art solutions that enable textile manufacturers worldwide to thrive in the competitive market. With a portfolio of groundbreaking machinery, [Company Name] continues to push the boundaries of what is possible in the textile industry.

Loom Machine - Find Affordable Options for Sale

Loom Machine For Sale: Revolutionizing the Textile IndustryThe textile industry plays a vital role in our day-to-day lives, from the clothes we wear to the fabrics that adorn our homes. With the increasing demand for textiles, there is a need for advanced machinery that can handle large-scale production efficiently. One company that has been at the forefront of revolutionizing the textile industry is {Company Name}.{Company Name} is a leading manufacturer and supplier of cutting-edge textile machinery that caters to the needs of the global market. With a strong reputation built on years of experience and innovation, the company is known for its commitment to delivering high-quality and reliable machinery to meet the diverse requirements of textile manufacturers.One of the most notable offerings from {Company Name} is their state-of-the-art loom machine, which has garnered widespread attention in the industry. The loom machine is a fundamental tool used in weaving fabrics, and the advancements introduced by {Company Name} have revolutionized the production process.The loom machine for sale by {Company Name} boasts a plethora of advanced features, designed to enhance productivity, efficiency, and overall performance. The machine is equipped with the latest technology, including automation capabilities, programmable settings, and user-friendly interfaces, making it easier for textile manufacturers to adapt and streamline their operations.One of the standout features of the loom machine is its high-speed weaving capability. With the ability to produce fabrics at an unprecedented rate, manufacturers can significantly increase their production output, thus meeting the ever-growing demands of the market. This accelerated production speed not only boosts efficiency but also translates into substantial cost savings for textile manufacturers.Furthermore, {Company Name}'s loom machine offers exceptional versatility, as it can handle various types of fabrics efficiently. From delicate silk to heavy-duty denim, the machine ensures consistent and precise weaving, resulting in superior quality fabrics. This adaptability makes it an ideal choice for manufacturers looking to diversify their product offerings and cater to a wider range of customers.In addition to its functionality, the loom machine also prioritizes sustainability. With an increasing focus on eco-friendly practices, textile manufacturers are seeking machinery that minimizes waste and optimizes energy consumption. {Company Name}'s loom machine incorporates innovative features that promote sustainable production, such as efficient power usage and intelligent material handling systems. By reducing waste and energy consumption, manufacturers can not only save on costs but also contribute to a greener future.{Company Name} prides itself not only on the quality of its products but also on its dedication to customer satisfaction. Their team of highly skilled professionals works closely with clients to understand their unique requirements and provide tailored solutions. From installation and training to ongoing technical support, {Company Name} ensures a seamless experience for its customers, guaranteeing maximum performance and longevity of their machinery.With a global clientele that spans across countries, {Company Name} has established itself as a trusted partner in the textile industry. Their commitment to innovation and customer satisfaction has enabled them to strengthen their position as a market leader, continually exceeding expectations and setting new standards in the field of textile machinery.In conclusion, {Company Name}'s loom machine for sale has revolutionized the textile industry with its cutting-edge features and commitment to sustainability. The machine's high-speed weaving capabilities, versatility, and user-friendly interface make it an invaluable asset for textile manufacturers aiming to increase productivity and efficiency. With {Company Name}'s unwavering dedication to customer satisfaction and a reputation built on innovation, it comes as no surprise that their loom machine is highly sought after by textile manufacturers worldwide.

What Does Loom Mean? Definition, Usage, and Synonyms.

IntroductionLooms have been around for centuries, revolutionizing the textile industry with their ability to weave and create complex designs for clothing, rugs, and other fabrics. But what exactly is a loom? In this blog post, we will explore the definition and meaning of looms, as well as how they are used and their significance in the textile industry. We will also discuss the importance of looms for home use, particularly with the rise in popularity of home loom machines.Definition and MeaningAccording to the Oxford Dictionary, a loom is "a machine for weaving fabric by interlacing threads at right angles." In simpler terms, looms are tools used to create textiles by interweaving threads to create patterns and designs. Looms can range from small, hand-held devices to large, industrial machines used in textile factories.Looms have played a significant role in human history, with evidence of loom use dating back to ancient civilizations like the Egyptians and Greeks. The invention of the power loom during the Industrial Revolution in the 19th century revolutionized the textile industry, allowing for faster and more efficient production of textiles.How to Use a LoomUsing a loom requires skill and practice. The process of weaving involves setting up the warp (lengthwise) and weft (horizontal) threads on the loom. The weaver then manually moves the shuttle back and forth to weave the weft threads through the warp threads, creating the desired pattern or design. Different looms have different weaving techniques and capabilities, allowing for a wide range of intricate designs and patterns to be created.Home Loom MachinesWith the rise in popularity of DIY and home crafting, home loom machines have become increasingly popular. These machines are smaller and more compact than traditional looms, making them easier to use and store in a home environment. They also often come with pre-programmed patterns and designs, making it easier for beginners to create beautiful textiles without extensive weaving experience.Home loom machines have become a popular choice for hobbyists and those looking to start small textile businesses from their homes. They offer the freedom to create unique designs and patterns, and the ability to easily experiment with different materials and fibers. Additionally, home looms can be a great way to practice mindfulness, as the process of weaving requires focus and attention to detail.Synonyms for LoomSome synonyms for loom include weaving machine, textile machine, and Jacquard loom (a type of loom used to create intricate and complex patterns).ConclusionIn conclusion, looms are an essential tool for creating textiles, from clothing to rugs and other fabrics. They have played a significant role in human history and continue to be an important component of the textile industry. With the rise in popularity of home crafting, home loom machines have become a popular choice for those looking to create unique textiles from the comfort of their own home. Looms offer a way to express creativity, practice mindfulness, and develop valuable weaving skills.

Circular Weaving Machine: Innovating the Textile Industry with Advanced Technology

Title: Revolutionary Circular Weaving Machine: A Breakthrough in Textile ManufacturingIntroduction:The textile industry is on the brink of a technological revolution with the introduction of an innovative Circular Weaving Machine. Developed by a leading textile machinery manufacturer (company name), this groundbreaking piece of equipment is set to transform the industry by offering unprecedented speed, efficiency, and versatility in fabric production. This article provides an in-depth overview of the Circular Weaving Machine and explores its potential to revolutionize the textile manufacturing landscape.Unveiling the Circular Weaving Machine:The Circular Weaving Machine is a state-of-the-art textile manufacturing equipment that combines advanced technology and engineering expertise to deliver remarkable performance. Its groundbreaking design eliminates the limitations of traditional weaving machines, making it an unparalleled asset for textile manufacturers worldwide.Key Features and Benefits:1. Enhanced Speed and Efficiency:The Circular Weaving Machine is capable of producing fabrics at an unrivaled speed, significantly boosting overall production efficiency. The machine incorporates cutting-edge automation and streamlined processes, reducing downtime and increasing throughput. Manufacturers can expect higher yields and improved productivity when utilizing this advanced equipment.2. Versatility in Fabric Creation:One remarkable aspect of the Circular Weaving Machine is its ability to produce a wide range of fabrics. Whether it is delicate silk, sturdy denim, or intricate patterns, the machine accommodates various materials and designs. This versatility empowers textile manufacturers to diversify their product offerings, catering to the ever-changing consumer demands.3. Reduced Resource Consumption:In line with the growing global focus on sustainability, the Circular Weaving Machine is designed to minimize resource consumption during the manufacturing process. By optimizing the usage of raw materials, energy, and water, this innovative equipment significantly reduces the carbon footprint associated with textile production. Additionally, the machine employs eco-friendly manufacturing techniques that contribute to a greener future.4. Remote Monitoring and Maintenance:To ensure seamless operation and minimal downtime, the Circular Weaving Machine leverages cutting-edge remote monitoring and maintenance capabilities. Real-time monitoring allows manufacturers to track production parameters, identify potential issues, and make timely interventions. This feature substantially improves operational efficiency and minimizes maintenance costs.Market Impact and Industry Outlook:The arrival of the Circular Weaving Machine in the textile industry marks a significant turning point. Manufacturers who adopt this groundbreaking technology gain a competitive edge in today's rapidly evolving market. The machine's ability to meet increasing consumer demands, coupled with heightened production efficiency, positions companies utilizing it for unprecedented growth potential.Additionally, the Circular Weaving Machine prepares the textile industry for the future by aligning it with ethical and sustainable manufacturing practices. As consumers increasingly demand transparency and eco-friendly products, this technology enables manufacturers to meet these expectations head-on.Conclusion:The introduction of the Circular Weaving Machine represents a pivotal moment for the textile industry, revolutionizing fabric production and manufacturing practices. Through its remarkable speed, versatility, resource efficiency, and advanced monitoring capabilities, this cutting-edge equipment empowers textile manufacturers to excel in an evolving market.As the world embraces sustainable practices, the Circular Weaving Machine offers a viable solution for producing eco-friendly textiles, reducing waste, and conserving resources. With its countless benefits, this revolutionary machine is poised to redefine the textile manufacturing landscape and shape the future of the industry.