Facts and Figures About Watch Movements: Your Ultimate Guide

Felsa Watch Movements: A Complete GuideFelsa Watch Movements are considered the most reliable and efficient watch movements in the world of watchmaking. The brand has a rich history that dates back to 1923 when the company started producing its first-ever mechanical watch movements. Today, Felsa Watch Movements are the most sought-after and desired movements in the watchmaking industry due to their accuracy and precision.What are Felsa Watch Movements?Felsa Watch Movements are mechanical movements that are used in the watchmaking industry. The brand produces different types of movements from hand-winding movements to automatic movements. Felsa movements are known for their superior quality and accuracy.Types of Felsa Watch MovementsFelsa produces a wide range of watch movements. Here are some of the most popular movements produced by the brand:1. Felsa 4002The Felsa 4002 is a hand-winding movement that is known for its accuracy and reliability. The movement has 17 jewels and a power reserve of 40 hours. It also has a frequency of 18,000 vph.2. Felsa 690The Felsa 690 is an automatic movement that is used in some of the most popular watch brands. The movement has 21 jewels and a power reserve of approximately 42 hours. It also has a frequency of 28,800 vph.3. Felsa 1560The Felsa 1560 is a manual-winding movement that was produced in the 1950s. The movement has 17 jewels and a power reserve of approximately 38 hours. It was known for its accuracy and reliability.4. Felsa 693The Felsa 693 is an automatic movement that is known for its accuracy and efficiency. The movement has 25 jewels and a power reserve of approximately 42 hours. It also has a frequency of 28,800 vph.5. Felsa 690-2The Felsa 690-2 is an automatic movement that was produced in the 1970s. The movement has 25 jewels and a power reserve of approximately 42 hours. It also has a frequency of 28,800 vph.Benefits of Felsa Watch MovementsFelsa Watch Movements are known for their superior quality and accuracy. The brand produces some of the most reliable and efficient movements in the watchmaking industry. Here are some of the benefits of Felsa Watch Movements:1. AccuracyFelsa Watch Movements are known for their accuracy. The brand produces some of the most accurate movements in the watchmaking industry.2. ReliabilityFelsa Watch Movements are also known for their reliability. The brand produces some of the most reliable movements in the watchmaking industry.3. DurabilityFelsa Watch Movements are durable and can last for a long time. The brand uses high-quality materials to produce their movements, which ensures their durability.4. VersatilityFelsa Watch Movements are versatile and can be used in different types of watches. The brand produces hand-winding, automatic, and manual-winding movements.ConclusionFelsa Watch Movements are the most reliable and efficient movements in the watchmaking industry. The brand produces some of the most accurate and durable movements that can last for a long time. Felsa Watch Movements are also versatile and can be used in different types of watches. If you are looking for a high-quality movement for your watch, then Felsa is the brand you should consider.

Read More

How to Use Pulleys in Your Mechanical Projects

Pulley systems are often considered one of the most important inventions in modern history. They have revolutionized the way people work, and have greatly impacted industries such as construction, manufacturing, and transportation.Recently, a new pulley system has been developed that promises to take this technology to a whole new level. By combining advanced materials and cutting-edge design techniques, this new pulley system is set to transform the way people work and revolutionize entire industries.Leading the charge in this exciting new venture is a company that has made a name for itself in the industry as an innovative leader in the field of pulley technology. This company has a proven track record of developing high-quality, reliable pulley systems that have been used around the world in a variety of applications.With the development of this new pulley system, this company is once again cementing its position as a leader in the industry. The new system features a range of innovative features that are designed to improve usability and efficiency while maintaining the exceptional quality and reliability that the company is known for.One of the most notable features of this new pulley system is its use of advanced materials. The system utilizes high-strength materials that are designed to withstand extreme loads and pressures, making it ideal for use in demanding applications such as heavy construction and manufacturing.In addition to its use of advanced materials, the new pulley system also features a unique design that is optimized for maximum efficiency. The system has been engineered to reduce friction and minimize energy loss, allowing it to operate more smoothly and efficiently than traditional pulley systems.The result of this innovative design is a pulley system that is not only more efficient and reliable than traditional systems, but also easier to use and more versatile. The system can be customized to suit a wide range of applications, making it ideal for use in a variety of industries.Despite its many advantages, the new pulley system is surprisingly affordable, thanks to the company's commitment to keeping costs low. This commitment is reflected in the system's price tag, which is highly competitive with other high-end pulley systems on the market.Overall, the new pulley system is an exciting development for the industry and promises to have a significant impact on the way people work. By combining advanced materials and innovative design techniques, this new system is poised to revolutionize entire industries and help to drive innovation and progress across a wide range of fields.As the company behind this exciting new development, {} is proud to be at the forefront of this innovative technology. With its commitment to excellence and its dedication to delivering high-quality, reliable products, this company is poised to continue leading the way in the field of pulley systems for years to come.

Read More

When it comes to organizing data, creating graphs and charts is an effective way to visually display information. And one of the most popular types of graphs is the XY axis graph. With its ability to show the correlation and relationship between two variables, the XY axis graph is a staple in data analysis and visualization.But creating an XY axis graph can be a challenge, especially if you're working with a large set of data. That's where the XY magnet comes in – a tool that simplifies the process of creating and organizing XY axis graphs.The XY magnet is a 45.25" tall by 45.25" wide magnetic sheet that serves as the foundation for your XY axis graph. With its strong magnetic properties, you can easily move and adjust data points without the hassle of sticky papers or fragile components.One of the benefits of using the XY magnet is its flexibility. Unlike traditional paper or whiteboard, the XY magnet allows you to quickly make changes and adjustments to your graph. Need to add another data point? Simply move it to the proper location. Want to change the scale of your graph? Just adjust the magnets accordingly.Another advantage of the XY magnet is its ability to streamline the graphing process. By having a single surface to work on, you can easily compare and contrast data points, and make informed decisions about your presentation. And since the XY magnet is reusable, you can create multiple graphs without wasting materials.If you're worried about the safety of your data, don't be. The XY magnet has a strong hold, so your data points won't slip or fall off accidentally. Plus, the magnet is made from durable materials that can withstand frequent use and handling.In summary, the XY magnet is an innovative tool that simplifies the process of creating XY axis graphs. Its flexibility, ease of use, and reusable nature make it an invaluable asset for data analysts, researchers, and educators. So if you're looking to streamline your graphing process and make data analysis a breeze, consider investing in the XY magnet today.

Read More

Ancient Weaving Machine: The History and Evolution of Looms

Looms have been around for thousands of years, starting from the 5th millennium BC. Over the years, they have evolved into machines that are highly efficient and capable of weaving complex patterns and designs.A loom is a machine that is used for weaving cloth. It consists of several components, including a frame, a warp, and a weft. The frame is used to hold the warp threads in place, while the weft is passed over and under the warp threads to create the fabric.There are various types of looms available, including handlooms, power looms, and computerized looms. Each type of loom has its own advantages and disadvantages, depending on the requirements of the user.Handlooms are the oldest type of loom, and they are still used in some parts of the world today. They are simple to use and require no external energy source, making them perfect for use in remote areas. However, they are slow and can only produce small quantities of fabric at a time.Power looms, on the other hand, are used in factories and are capable of producing large quantities of fabric in a short amount of time. They are faster and more efficient than handlooms, but they require a lot of power and are expensive to maintain.Computerized looms are the newest type of loom and are used in modern textile factories. They are highly automated and can produce complex designs and patterns with ease. They are also the most expensive type of loom and require skilled operators to use them.Weaving is an essential part of the textile industry, and the loom plays a critical role in the process. Without the loom, it would be impossible to produce the vast quantities of fabric required by the fashion industry today.In conclusion, the loom is an essential machine used for weaving cloth. It has a rich history, dating back to the 5th millennium BC. Over the years, it has evolved into different types, each with its own set of advantages and disadvantages. Whether you are using a handloom, power loom, or computerized loom, the loom is one of the most important machines used in the textile industry today.

Read More

Learn How to Knit Socks Using Magic Loop with this PDF Pattern and Video Guide

If you are a knitting enthusiast or have always been fascinated by the art of knitting, then you must have heard about the magic loop knitting technique. The magic loop technique is the perfect way to knit small circular projects, especially socks. And if you are looking for a comprehensive pattern to help you knit your first pair of socks on magic loop, then Twin Stitches Designs has got you covered.The Socks With Magic Loop-Knitting PDF Pattern by Twin Stitches Designs is the ideal pattern for anyone who is looking for detailed instructions on the magic loop knitting technique. This pattern is not just a standard knitting pattern, but it comes with a video tutorial on YouTube that covers all the techniques involved in this pattern.The video tutorial is perfect for beginners who are new to magic loop knitting and need help with mastering the technique. The tutorial covers all the important techniques of knitting socks, including how to cast on, knit, purl, decrease, and bind off. In addition, the video has step-by-step instructions on how to create a magic loop for knitting small circular projects.The pattern is available in three sizes, including small, medium, and large. It also comes with a sock factory theme that makes the project exciting and fun to work on. The pattern has detailed instructions on how to knit the socks, including the number of stitches, rows, and decreases required to make a pair of socks.Overall, this pattern is perfect for anyone who wants to learn the magic loop knitting technique and create their first pair of socks. It is also an excellent option for individuals who are looking for a fun and unique project to work on. So, if you are looking for a high-quality sock pattern with instructions on the magic loop knitting technique, then the Socks With Magic Loop-Knitting PDF Pattern by Twin Stitches Designs is a great option. And don't forget to include the keywords Magic Loop Knitting Socks Factory in your search to easily find this pattern online.

Read More

Evolution and History of Mechanized Knitting Production

Knitting machinery has revolutionized the textile industry and has been instrumental in the mass production of fabrics. Before the advent of machines, knitting was largely a manual process, done in cottages as a means of earning a livelihood. The earliest knitting machine was invented in the sixteenth century by William Lee, called the circular knitting machine. With time, such machinery became more advanced and efficient, and knitting machines became a crucial component of the textile industry.The first weaving machine, in contrast, predates the invention of the knitting machine by several centuries. Weaving has been practiced for thousands of years by various cultures around the world. Weaving machines were developed in ancient civilizations such as those of Greece, Rome, and China. In the early Middle Ages, looms were operated manually and powered by human or animal power.The development of power weaving machines began in the early eighteenth century in England, where the Industrial Revolution was in full sway. The first power looms were invented in 1785 by Edmund Cartwright. These looms used water power to drive the weaving mechanism, and they were large and expensive. However, they significantly increased the speed and efficiency of textile production.Both knitting and weaving machines have continued to evolve over the years. Today, there are various types of knitting machines that produce fabrics of different types and textures. Some knitting machinery can even create seamless garments with complex shapes and patterns. In contrast, weaving machines have diversified to produce intricate designs and materials with a wide range of properties, such as stretch, elasticity, and thickness.The knitting and weaving processes are quite different, with different applications and uses. Knitting involves the interlocking of loops of yarn or thread to create a fabric. In contrast, weaving involves the interlacing of two sets of yarns, the warp, and the weft, to create a stable fabric. Knitted fabrics tend to be stretchy, whereas woven fabrics can be either stiff or flexible, depending on the material and weave pattern.In conclusion, the advent of knitting and weaving machines has been critical in the history of the textile industry. Knitting machines have been essential in the mass production of fabrics, while weaving machines have been used to produce a wide range of materials and designs. The evolution of these machines has resulted in the widespread availability of affordable textiles and clothing. Today, both knitting and weaving machines continue to be used in the textile industry, meeting the demands of consumers worldwide.

Read More

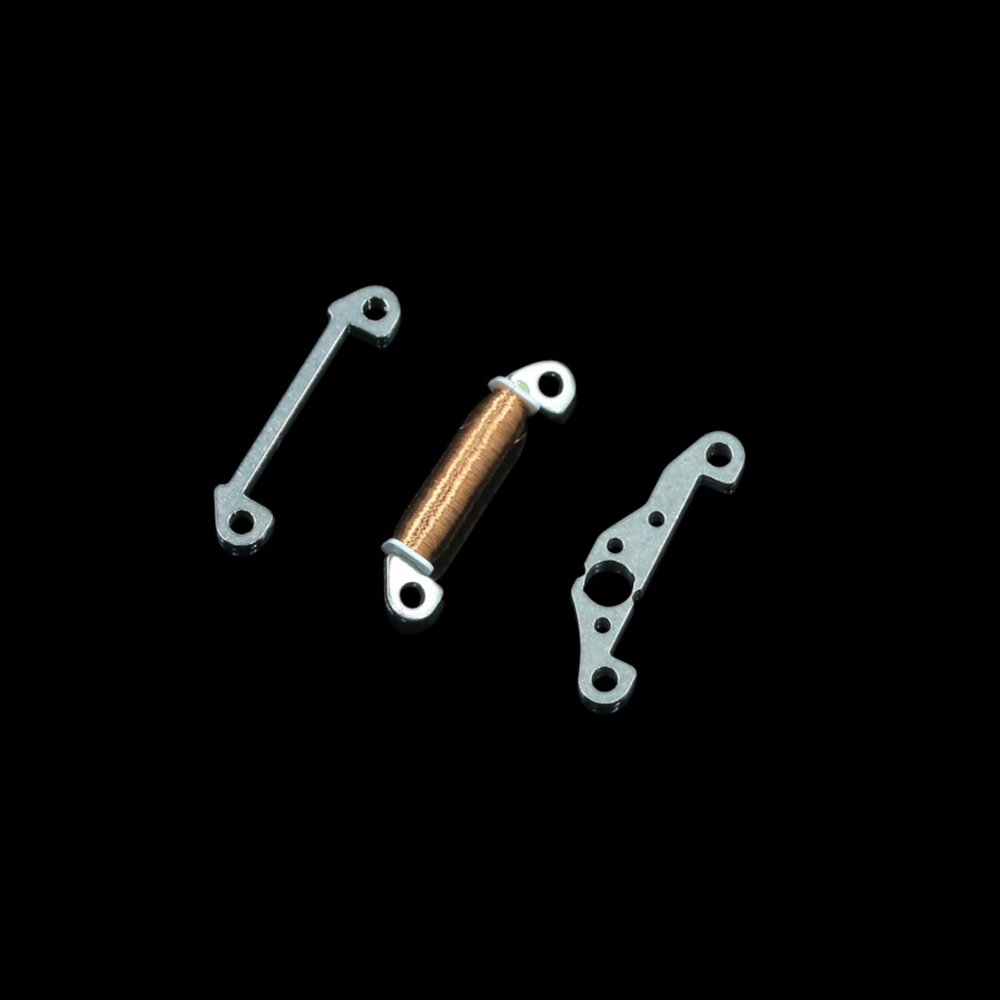

Comparison of 21,600 bph Automatic Mechanical Clone Watch Movements: 2813 vs 2836

, 2836 Automatic Movement, Clone Watch Movement, Date Wheel Overlay, BPH.When it comes to clone watch movements, there are a few options available in the market. Two of the most popular ones are the 2813 and 2836 automatic mechanical movements. While both of these movements have some similarities, there are also some differences that set them apart.One of the first differences between these two movements is the price. While the 2813 movement is about 1/3 of the cost of the 2836, it is still a good option for those who are looking for a reliable automatic movement for their clone watch. However, if you want to go for a more high-end option, the 2836 may be a better choice.Both the 2813 and 2836 movements have a date position that sits above the movement, which makes them easier to fit with a date wheel overlay. This is a useful feature for those who want to add a date feature to their watch. However, it is important to note that these movements are different from the genuine movements, and may not provide the same accuracy or durability.The 2813 movement has a frequency of 21,600 beats per hour (BPH), which is a common frequency for clone watch movements. This frequency provides a good balance between accuracy and power reserve, and is suitable for most clone watches. On the other hand, the 2836 movement has a higher frequency of 28,800 BPH, which provides smoother and more accurate movement. However, this also puts more strain on the movement, and may require more maintenance.When choosing between the 2813 and 2836 movements, it ultimately comes down to personal preference and budget. While both of these movements have their pros and cons, they are both good options for clone watch movements. It is important to choose a trustworthy supplier who can provide you with high-quality clone parts and a reliable movement.In conclusion, the 2813 and 2836 automatic mechanical clone watch movements are both good options for those who want to add an automatic movement to their clone watch. While the 2813 is a more affordable option, the 2836 provides a higher frequency and smoother movement. Both of these movements have a date position that sits above the movement, which makes them easier to fit with a date wheel overlay. When choosing between the two, it is important to consider your personal preferences and budget.

Read More

Electrifying Performance by Musical Sensations at Spokane's Knitting Factory Concert House - January 23, 2020

Concert House Spokane Black Tiger Sex Machine January 23 2020.On January 23rd, 2020, the Spokane Knitting Factory Concert House was the place to be for all EDM fans in the area, as the highly anticipated Black Tiger Sex Machine show sold out in a matter of days. The Canadian trio known for their dubstep-infused style and powerful stage presence had been making waves in the electronic music scene for years, and their live performances were always a sight to behold.The concert opened with an explosive set by local DJ Sentro, who warmed up the crowd with his signature blend of house and techno beats. The energy in the venue was palpable as the crowd danced and cheered, eagerly awaiting the headlining act. When Black Tiger Sex Machine finally took the stage, the audience roared in excitement, and the group wasted no time in getting the party started.The trio's performance was nothing short of mesmerizing. The setlist included a mix of their biggest hits and newer tracks, all infused with their trademark aggressive basslines, intricate sound design, and haunting vocals. The stage setup was also a marvel to behold, with elaborate lighting and visuals that perfectly complemented the music.Despite the high-energy nature of their performance, Black Tiger Sex Machine didn't neglect the finer details of their music. The precision of their live mixing and the intricate layers of their soundscapes were evidence of their dedication to their craft. The show was truly an audiovisual feast, and the crowd responded accordingly, dancing and shouting throughout the entire set.As the night wore on, the energy in the venue reached its peak with the trio's final track, "Survivors". The crowd sang along to the infectious chorus as Black Tiger Sex Machine delivered their trademark drop. The spectacle of the flashing lights, pounding bass, and frenzied crowd was truly unforgettable.The Spokane Knitting Factory Concert House was the perfect venue for this epic performance, and it's clear that Black Tiger Sex Machine knows how to put on a show. Their fusion of heavy basslines, intricate sound design, and electrifying visuals has truly set them apart in the EDM world. And with the help of opening act Sentro and the dedicated audience, their performance at the Spokane Knitting Factory Concert House was truly legendary.In conclusion, the Black Tiger Sex Machine performance at the Spokane Knitting Factory Concert House was a highly anticipated and unforgettable event for EDM fans in the area. The trio's dedication to their craft, their high-energy performance, and their intricate sound design make them one of the most exciting acts in the electronic music scene today. And with the help of opening act Sentro and the dedicated audience, the night was truly unforgettable. If you missed this show, be sure to catch them the next time they're in town!

Read More

Qualities that Make Watch Movements Accurate and Reliable

When it comes to purchasing a watch, accuracy and reliability are two key factors that most people consider. The movement of a watch, whether mechanical or quartz, is responsible for its accuracy and reliability. Let's dive into what makes a watch movement accurate and reliable.Mechanical MovementsMechanical watches operate without the use of batteries or electronic components. Instead, they rely on a complex series of gears, springs, and other mechanical parts to keep time. One of the factors that make mechanical movements accurate is the use of a balance wheel. The balance wheel oscillates back and forth, and the speed of its oscillation determines the accuracy of the timekeeping.Additionally, mechanical movements are manually wound, which means that you have to wind the watch to keep it running. This creates a consistent and even energy flow to the balance wheel. However, mechanical watches can be affected by external factors such as gravity or temperature changes.Reliability is also important when it comes to mechanical watches. A well-maintained mechanical watch can last for generations. However, due to the complexity of the movement, a mechanical watch requires regular servicing to ensure that it operates correctly.Quartz MovementsQuartz watches use electronic components to keep time. The movement contains a small quartz crystal that vibrates at a specific frequency when a current is applied. The frequency is stable and constant, making quartz watches extremely accurate.Unlike mechanical watches, quartz movements rely on a battery to keep them running. The battery powers an electronic circuit that sends a pulse to the crystal, which in turn regulates the movement of the watch. Quartz watches are less affected by external factors such as temperature changes and can maintain accuracy over long periods of time.In terms of reliability, quartz watches are known for their durability and low maintenance requirements. They don't require regular servicing like mechanical watches, and the battery can be easily replaced when it runs out.Accuracy Movement WatchesWhen it comes to accuracy, both mechanical and quartz movements have their strengths and weaknesses. Mechanical watches offer a traditional feel and require more maintenance, but they can last for generations if cared for correctly. In contrast, quartz watches are extremely accurate and require minimal maintenance.However, advancements in technology have allowed watchmakers to combine the best of both worlds. There are now hybrid watches that use a combination of mechanical and quartz movements. These watches offer the traditional appeal of a mechanical watch with the accuracy of a quartz movement.To ensure that your watch is accurate and reliable, it's important to purchase from a reputable brand and take care of it properly. Regular servicing can help maintain accuracy and extend the lifespan of your timepiece.In conclusion, whether you prefer a mechanical watch or a quartz watch, accuracy and reliability are important factors to consider. The movement of the watch is responsible for its accuracy and reliability, and advancements in technology have allowed watchmakers to create hybrid watches that offer the best of both worlds. With proper care and maintenance, a watch can last for generations and remain a reliable timekeeping companion.

Read More

Production of Jacquard units slashed by 30% due to declining demand for saris

Title: The Declining Demand for Jacquard Saris: The Impact on Indian Jacquard Weaving UnitsIntroduction (50 words):In recent times, the demand for jacquard saris in India has experienced a significant decline, leading to a substantial decrease in production for thousands of jacquard weaving units across the country. This blog will delve into the reasons behind this fall in demand, the consequences for the industry, and the potential implications for local weavers.Keywords: Jacquard Loom in Hindi, Jacquard Saris, Indian Jacquard Weaving Units1. The Historical Significance of Jacquard Loom in Hindi (150 words):The jacquard loom, often referred to as "Jacquard takli" in Hindi, holds immense historical significance in India's rich textile heritage. Named after its inventor Joseph-Marie Jacquard, this automated weaving technology revolutionized the traditional handloom weaving process by enabling complex patterns and designs.2. The Rise and Fall: Understanding the Demand for Jacquard Saris (200 words):Jacquard saris, known for their intricate patterns and vibrant colors, have been an integral part of Indian fashion for centuries. However, the changing fashion preferences of consumers, influenced by globalization and a growing desire for contemporary designs, have resulted in a decline in demand for traditional jacquard saris.3. Economic Impact: The Plight of Jacquard Weaving Units (200 words):The recent dip in demand has forced jacquard weaving units across India to cut down their production by a staggering 30%. These units, typically employing skilled artisans, are facing financial strain and job insecurity due to the reduced orders. The impact is not limited to the loss of employment but also affects raw material suppliers and other auxiliary industries dependent on the jacquard sector.4. The Challenges of Adapting to Changing Market Trends (200 words):To survive in a rapidly evolving fashion market, jacquard weaving units need to adapt to changing consumer preferences and incorporate modern designs. The traditional motifs and patterns need to be fused with contemporary elements to attract younger buyers. Embracing digital marketing strategies, such as e-commerce platforms and social media, can also help reach a wider audience.5. Innovations and Solutions: Preserving the Heritage (200 words):To revive the demand for jacquard saris, it is crucial to invest in research and development to create innovative designs that blend tradition with modernity. Collaborations between designers and weavers can help craft unique collections that capture the attention of the international market.6. Government Support and Initiatives (150 words):Recognizing the plight of the jacquard weaving units, the government must provide financial assistance, skill development programs, and technological support to enable weavers to adapt to changing dynamics. Additionally, promoting jacquard saris through campaigns, workshops, and exhibitions can help raise awareness and generate demand.Conclusion (50 words):The fall in demand for jacquard saris has adversely affected the industry, leading to reduced production and job losses for weaving units. By embracing modern designs, incorporating digital marketing strategies, and receiving government support, the jacquard weaving sector can aim to revive its fortunes.Keywords: Jacquard Loom In Hindi, Jacquard Saris, Indian Jacquard Weaving Units

Read More