High-quality Knitting Machine Parts for Sale - Complete Range Available

By:Admin

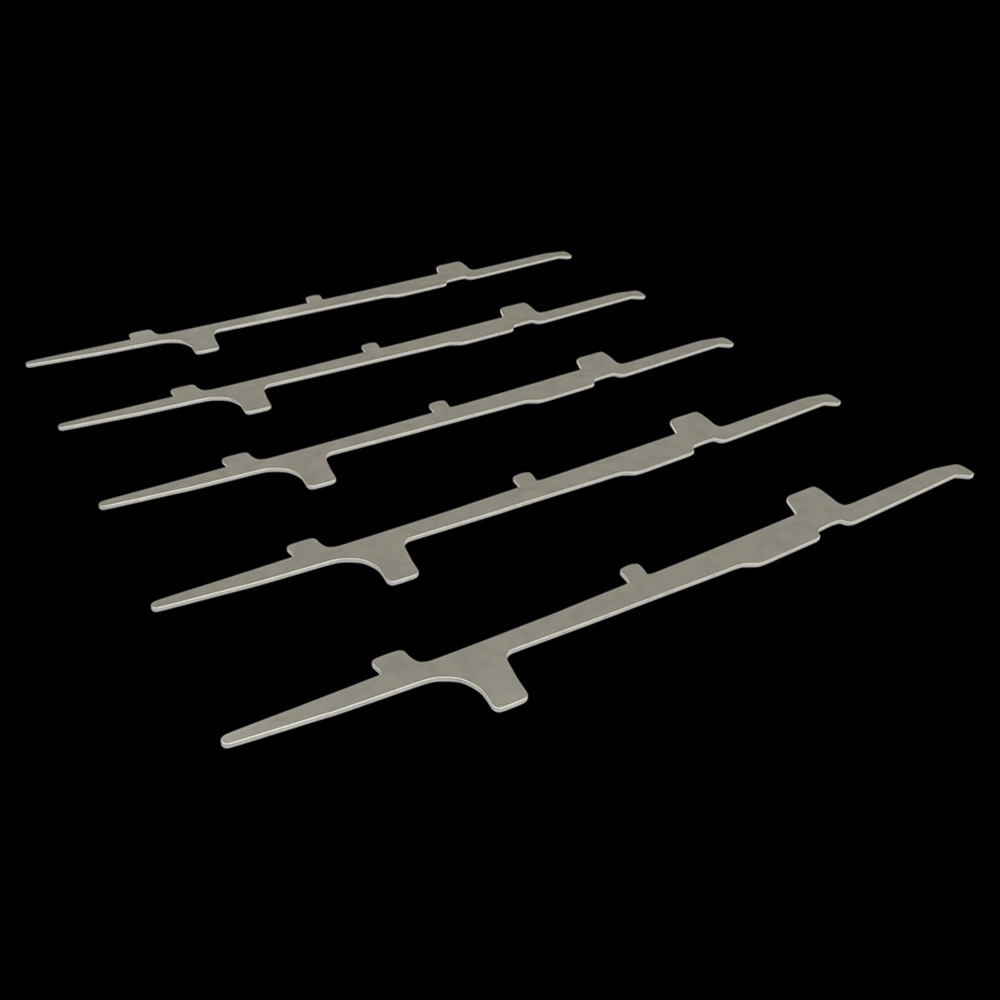

Established in [year], Sentro Knitting Machine Parts has continuously strived to meet the demands of an ever-evolving market. The company's extensive range of products includes needles, sinkers, yarn carriers, and various other components for knitting machines. These parts are designed to meet the highest standards of quality and are compatible with a wide variety of knitting machine models, making Sentro Knitting Machine Parts the go-to choice for many knitting enthusiasts and industry professionals.

One of the key factors that sets Sentro Knitting Machine Parts apart from its competitors is its unwavering dedication to research and development. The company invests heavily in cutting-edge technology and machinery to ensure that its products are at the forefront of innovation. This relentless pursuit of excellence has enabled Sentro Knitting Machine Parts to consistently deliver top-notch products that meet the diverse needs of its customers.

In addition to its commitment to quality, Sentro Knitting Machine Parts also places great emphasis on customer satisfaction. The company takes pride in its ability to provide exceptional customer service and support. Whether customers are in need of technical assistance or advice on selecting the right parts for their knitting machines, Sentro Knitting Machine Parts is always ready to lend a helping hand. This dedication to customer care has fostered strong relationships with clients around the world and has contributed to the company's continued success.

Furthermore, Sentro Knitting Machine Parts understands the importance of sustainability and environmental responsibility. The company operates with a keen awareness of its environmental impact and is dedicated to implementing eco-friendly practices in its operations. From utilizing recyclable materials in its packaging to implementing energy-efficient processes in its facilities, Sentro Knitting Machine Parts is committed to minimizing its carbon footprint and contributing to a greener planet.

As a company that prioritizes excellence, innovation, and customer satisfaction, Sentro Knitting Machine Parts has built a solid foundation for continued growth and success. Its dedication to producing high-quality products, providing exceptional customer service, and embracing environmental sustainability has earned it a sterling reputation in the industry.

To further strengthen its position as a leader in the knitting machine parts market, Sentro Knitting Machine Parts is constantly looking for new opportunities to expand its product line and reach new customers. The company is exploring partnerships with distributors and retailers to make its products more widely available and accessible to knitting enthusiasts worldwide.

In conclusion, Sentro Knitting Machine Parts continues to set the standard for excellence in the knitting machine parts industry. With its unwavering commitment to quality, innovation, and customer satisfaction, the company is poised to build on its success and remain a trusted partner for all knitting machine needs.

Company News & Blog

Production of Jacquard units slashed by 30% due to declining demand for saris

Title: The Declining Demand for Jacquard Saris: The Impact on Indian Jacquard Weaving UnitsIntroduction (50 words):In recent times, the demand for jacquard saris in India has experienced a significant decline, leading to a substantial decrease in production for thousands of jacquard weaving units across the country. This blog will delve into the reasons behind this fall in demand, the consequences for the industry, and the potential implications for local weavers.Keywords: Jacquard Loom in Hindi, Jacquard Saris, Indian Jacquard Weaving Units1. The Historical Significance of Jacquard Loom in Hindi (150 words):The jacquard loom, often referred to as "Jacquard takli" in Hindi, holds immense historical significance in India's rich textile heritage. Named after its inventor Joseph-Marie Jacquard, this automated weaving technology revolutionized the traditional handloom weaving process by enabling complex patterns and designs.2. The Rise and Fall: Understanding the Demand for Jacquard Saris (200 words):Jacquard saris, known for their intricate patterns and vibrant colors, have been an integral part of Indian fashion for centuries. However, the changing fashion preferences of consumers, influenced by globalization and a growing desire for contemporary designs, have resulted in a decline in demand for traditional jacquard saris.3. Economic Impact: The Plight of Jacquard Weaving Units (200 words):The recent dip in demand has forced jacquard weaving units across India to cut down their production by a staggering 30%. These units, typically employing skilled artisans, are facing financial strain and job insecurity due to the reduced orders. The impact is not limited to the loss of employment but also affects raw material suppliers and other auxiliary industries dependent on the jacquard sector.4. The Challenges of Adapting to Changing Market Trends (200 words):To survive in a rapidly evolving fashion market, jacquard weaving units need to adapt to changing consumer preferences and incorporate modern designs. The traditional motifs and patterns need to be fused with contemporary elements to attract younger buyers. Embracing digital marketing strategies, such as e-commerce platforms and social media, can also help reach a wider audience.5. Innovations and Solutions: Preserving the Heritage (200 words):To revive the demand for jacquard saris, it is crucial to invest in research and development to create innovative designs that blend tradition with modernity. Collaborations between designers and weavers can help craft unique collections that capture the attention of the international market.6. Government Support and Initiatives (150 words):Recognizing the plight of the jacquard weaving units, the government must provide financial assistance, skill development programs, and technological support to enable weavers to adapt to changing dynamics. Additionally, promoting jacquard saris through campaigns, workshops, and exhibitions can help raise awareness and generate demand.Conclusion (50 words):The fall in demand for jacquard saris has adversely affected the industry, leading to reduced production and job losses for weaving units. By embracing modern designs, incorporating digital marketing strategies, and receiving government support, the jacquard weaving sector can aim to revive its fortunes.Keywords: Jacquard Loom In Hindi, Jacquard Saris, Indian Jacquard Weaving Units

Revolutionary Advances in Weaving Technology: The Cutting-Edge Jet Loom Machine

[Title: Advanced Loom Machine Revolutionizes Textile Industry][Subtitle: Company Name Introduces Revolutionary Loom Machine, Marking a Milestone in Textile Manufacturing][date][City, State] - The textile manufacturing industry recently witnessed a groundbreaking advancement with the introduction of an innovative and technologically advanced loom machine, developed by [Company Name]. This cutting-edge technology is set to revolutionize the production of textiles by increasing efficiency, improving quality, and reducing environmental impact.[Company Name], a leading provider of textile machinery solutions, has invested years of research and development to create a machine that encompasses the latest advancements in the industry. This breakthrough technology eliminates the limitations of traditional loom machines, offering substantial benefits to textile manufacturers worldwide.The new loom machine boasts several impressive features that elevate it above its predecessors. Firstly, its advanced automation and artificial intelligence capabilities significantly improve production efficiency. Through the integration of smart sensors and intelligent control systems, this machine can efficiently monitor and adjust various parameters, ensuring seamless operation and minimizing the risk of defects. With a higher production speed and reduced downtime, textile manufacturers can increase their output and meet rising market demands effectively.Additionally, the machine's versatility allows for enhanced customization and product diversity. By leveraging innovative weaving techniques and an intuitive user interface, operators can easily switch between different patterns, designs, and fabric types. This flexibility enables manufacturers to cater to changing market trends, while maintaining high-quality standards and meeting individual customer requirements.A key highlight of this advanced loom machine is its eco-friendly features. In an era where environmental sustainability is of utmost importance, [Company Name] has incorporated several energy-saving and waste-reducing mechanisms. The machine optimizes power consumption, resulting in reduced energy costs and a smaller carbon footprint. Additionally, the system employs sophisticated recycling systems to minimize material waste, further contributing to sustainable manufacturing practices.Speaking about the revolutionary loom machine, [Company Name]'s spokesperson stated, "We are thrilled to introduce this groundbreaking technology to the textile industry. Our aim has always been to equip manufacturers with cutting-edge solutions that streamline their operations, enhance productivity, and align with global sustainability goals. This loom machine epitomizes our commitment to innovation."Industry experts have commended [Company Name]'s contribution to the textile manufacturing field. Dr. Lisa Anderson, a textile engineer at a renowned research institution, remarked, "This advanced loom machine has the potential to transform the entire textile manufacturing landscape. Its automation capabilities will drive efficiency, while its eco-friendly features address the industry's pressing environmental concerns. It is a game-changer in every sense."Textile manufacturers worldwide are eagerly anticipating the availability of this revolutionary loom machine. It is expected to enable them to stay ahead in an increasingly competitive market while upholding the highest standards of quality and sustainability.In conclusion, [Company Name] has introduced a groundbreaking loom machine that promises to revolutionize the textile manufacturing industry. This cutting-edge technology offers enhanced automation, improved customization, and eco-friendly features, providing manufacturers with a competitive advantage and contributing to a more sustainable future. With [Company Name] at the forefront of innovation, the future of textile manufacturing looks brighter than ever before.

Review: Marvell-Powered SSD with a Twist

article on the Plextor M5S 256 GB SSD, focusing on its features and performance.Plextor M5S 256 GB Review: Marvell Inside, With A TwistThe latest addition to the Plextor M5S family is the 256 GB SSD, which offers a great combination of speed, reliability, and flexibility. The M5S is a solid-state drive that uses Marvell's 88SS9174-BLD2 controller, a 6 Gb/s SATA 3 interface, and the latest 25 nm MLC NAND flash memory.One of the standout features of the Plextor M5S 256 GB SSD is its impressive performance. The drive delivers read speeds of up to 520 MB/s and write speeds of up to 300 MB/s. These speeds make it one of the fastest SSDs on the market, and it's perfect for handling large files and running demanding applications.The M5S 256 GB SSD also features advanced features like TRIM and NCQ support, which optimize performance and prolong the life of the drive. The drive also has a robust and reliable design, with a long lifespan and impressive write endurance.Another great feature of the Plextor M5S 256 GB SSD is its flexibility. The drive comes with a variety of software tools that make it easy to manage and configure. These tools include the Plextool, which allows users to check the drive's status, health, and performance, and the PlexTurbo, which helps to improve performance by using system memory as a cache.In addition to these features, the Plextor M5S 256 GB SSD also has a few surprises up its sleeve. For example, Plextor has included a unique heat sink design in the drive, which helps to keep the drive cool and prevent overheating. This is a very useful feature for users who want to push the drive to its limits and run intensive applications.The Plextor M5S 256 GB SSD is also very easy to install and use. The drive comes with a comprehensive instruction manual and all the necessary cables and connectors. The installation process is very straightforward and takes just a few minutes to complete.In terms of pricing, the Plextor M5S 256 GB SSD is competitively priced, with a retail price of around $90. This makes it an affordable option for users who want a fast, reliable, and flexible SSD.Overall, the Plextor M5S 256 GB SSD is an excellent choice for users who want a high-performance SSD with advanced features and great flexibility. It's one of the fastest SSDs on the market and offers a range of features that make it easy to manage and configure. With its competitive pricing and impressive performance, the Plextor M5S 256 GB SSD is definitely worth considering.

Stay Up-to-Date with the Latest Search Trends: News and Insights for Search Engine Marketing, SEO and Paid Search

As the world becomes increasingly reliant on the internet, having search engine optimization (SEO) strategies in place has become more important than ever before. In order to improve search engine rankings and increase website traffic, businesses must ensure that they implement the right keywords and tactics.One key industry that can benefit greatly from SEO is the watch movement suppliers market. For businesses looking to stay ahead of the curve, incorporating the right keywords can make all the difference in boosting organic search results and driving sales.So, what are some tactics that watch movement suppliers can employ to improve their SEO strategies? Here are a few key factors to consider:1. Keyword ResearchThe first step when it comes to optimizing for SEO is conducting thorough keyword research. This involves identifying the specific keywords and phrases that customers are searching for when looking for watch movement suppliers. By targeting the right keywords, businesses can improve their chances of ranking higher in search engine results pages (SERPs), and ultimately driving more traffic to their site.Some potential keywords to consider for watch movement suppliers might include "watch movements," "watch movement parts," "watch movement suppliers," and "mechanical watch movements."2. On-Page OptimizationOnce businesses have identified the right keywords, they need to ensure that they're incorporating them into their website content effectively. This involves optimizing on-page elements such as meta descriptions, image tags, and header tags with targeted keywords. The goal is to ensure that search engines can easily crawl and index the website, and that customers can quickly find the information they need.3. Content MarketingAnother effective strategy for boosting SEO is incorporating content marketing tactics into your overall strategy. This involves creating high-quality, engaging content that is optimized for your target keywords and relevant to your audience's interests. This could take the form of blog posts, whitepapers, case studies, or other content that provides value to your customers and demonstrates your expertise in the watch movement supplier industry.By employing these tactics, watch movement suppliers can effectively improve their SEO efforts and drive more traffic to their websites. With targeted keywords, on-page optimization, and engaging content, businesses can stay ahead of the competition and attract more customers to their brand.

Solenoids Used in Textile Industry Witnessing High Demand in China

Title: China's Solenoid and Textile Industry Collaborate to Boost Manufacturing SectorIntroduction:China's solenoid and textile industries have recently joined forces in a collaborative effort aimed at enhancing the country's manufacturing sector. With both sectors individually showcasing commendable expertise and innovative solutions, the partnership has the potential to revolutionize various industries and drive economic growth. This article explores the synergistic alliance between China's Solenoid and Textile industry by highlighting their respective contributions and potential benefits to the manufacturing sector.1. Background of China's Solenoid Industry:China's solenoid industry has established itself as a global leader with its production of superior-quality, reliable, and efficient solenoid components. The industry has been instrumental in several sectors, including automotive, machine tools, aerospace, healthcare, and more. With robust research and development capabilities, advanced manufacturing techniques, and a focus on customer-centric solutions, China's solenoid industry has enjoyed continuous growth and international recognition.2. Overview of China's Textile Industry:China's textile industry is one of the largest globally, boasting a comprehensive supply chain, advanced production techniques, and a wide range of innovative textile products. The industry covers various sectors, including apparel, home textiles, technical textiles, and industrial textiles. China's textile industry has been at the forefront of innovation and sustainability, offering diverse products that cater to the changing demands of the global market.3. Collaboration for Enhanced Manufacturing Solutions:Recognizing the potential for synergy, the solenoid and textile industries in China have embarked on a collaborative endeavor. This union aims to combine their respective strengths and expertise to develop enhanced manufacturing solutions that will benefit a wide range of industries.4. Integration of Solenoid Components in Textile Manufacturing:The integration of solenoid components into textile manufacturing processes is set to revolutionize the sector. Solenoid valves, actuators, and control systems can play a vital role in automating various stages of production, including weaving, dyeing, printing, and finishing. By employing solenoid technology, the textile industry can improve efficiency, reduce wastage, eliminate human errors, and enhance overall productivity.5. Solenoid-Driven Innovations in Textile Machinery:China's solenoid industry offers a multitude of innovative solutions that can significantly enhance machinery used in the textile sector. By incorporating solenoid-driven components, textile machinery can achieve precise and efficient control, leading to greater textile quality, reduced energy consumption, and increased overall performance. This collaboration holds immense potential for addressing the evolving demands of the textile market.6. Advancing Sustainability in the Manufacturing Process:The partnership between solenoid and textile industries could contribute to advancing sustainability practices in manufacturing. By leveraging solenoid technology, manufacturers can achieve better control over production variables, resulting in reduced waste, optimized energy consumption, and improved resource management. This collaboration demonstrates a commitment to eco-friendly manufacturing practices, aligning with China's vision for sustainable development.7. Promoting IoT Integration for Smart Manufacturing:The integration of solenoid technology with the textile industry paves the way for smarter manufacturing processes. Through the Internet of Things (IoT), solenoid-driven textile machinery can gather and analyze data in real-time, fostering predictive maintenance, intelligent control, and improved overall equipment efficiency. This convergence of technologies aligns with the global trend of digitization and industrial automation.8. Potential Applications Beyond Textiles:While the immediate focus of this collaboration centers around textile manufacturing, the potential applications of solenoid technology extend far beyond textiles. The partnership between China's solenoid and textile industries opens doors for future developments in diverse sectors, including automotive, aerospace, healthcare, robotics, and more. These advancements have the potential to positively impact multiple industries, fostering growth and innovation.Conclusion:China's solenoid and textile industries are harnessing their collective strengths in a collaborative effort designed to enhance manufacturing solutions and boost economic growth. By integrating solenoid technology into textile manufacturing processes, the partnership aims to revolutionize the sector through improved efficiency, sustainability, and intelligent control. The vast potential of this collaboration extends beyond textiles, promising widespread benefits across various industries. This alliance presents an exciting opportunity for China's manufacturing sector and highlights its commitment to innovation in the global market.

Discover the Latest Advancements in Fuel Gauge Technology

[Company Name] Revolutionizes Fuel Monitoring with Innovative Auto Gauge Fuel Gauge[City], [Date] - [Company Name], a leading manufacturer of automotive parts and components, has recently introduced a groundbreaking product that promises to revolutionize fuel monitoring for vehicles. The Auto Gauge Fuel Gauge (brand name redacted) is set to provide accurate and real-time information about fuel consumption, allowing drivers to manage their fuel more efficiently and effectively.The Auto Gauge Fuel Gauge utilizes advanced technology and sensors to track fuel levels in real-time, ensuring drivers have accurate and up-to-date information about their remaining fuel reserves. Gone are the days of relying on outdated and unreliable fuel gauges that often give inaccurate readings, leaving drivers stranded with an empty tank.Building on their reputation as pioneers in automotive innovations, [Company Name] has been consistently at the forefront of developing cutting-edge solutions for the automotive industry. With their extensive research and development efforts, they have successfully engineered the Auto Gauge Fuel Gauge to address the common challenges faced by drivers regarding fuel monitoring.The Auto Gauge Fuel Gauge is designed to be compatible with a wide range of vehicle makes and models, making it a versatile and practical solution for all drivers. It can easily be installed in most vehicles without requiring extensive modifications or adjustments, ensuring a seamless integration into existing fuel systems.One of the key features of the Auto Gauge Fuel Gauge is its ability to provide real-time fuel consumption data. This feature enables drivers to track their fuel usage and make informed decisions about refueling, ensuring they never run out of fuel unexpectedly. By providing accurate and real-time fuel consumption information, the gauge also encourages more fuel-efficient driving habits, contributing to reduced emissions and environmental impact.Another notable feature of the Auto Gauge Fuel Gauge is its user-friendly interface. The gauge is equipped with a clear, easy-to-read display that provides drivers with comprehensive information, including fuel level, distance-to-empty, and fuel consumption rate. The interface also includes customizable settings, allowing drivers to personalize their experience and access the information they find most useful.Moreover, the Auto Gauge Fuel Gauge is equipped with advanced warning systems that alert drivers when fuel levels are critically low, helping them avoid potential inconvenience or dangerous situations. These alerts can be customized to suit individual preferences, ensuring drivers are promptly notified when the fuel level reaches a pre-defined threshold.In addition to the benefits for drivers, the Auto Gauge Fuel Gauge offers advantages to fleet management companies as well. By equipping their vehicles with this innovative technology, fleet managers can closely monitor fuel consumption, optimize route planning, and ensure their vehicles operate at maximum efficiency. This results in significant cost savings and improved operational performance for the entire fleet.[Company Name] takes pride in its commitment to quality and performance. To ensure the highest level of reliability and accuracy, every Auto Gauge Fuel Gauge undergoes rigorous testing and quality control measures. By adhering to stringent standards and regulations, [Company Name] ensures that their products deliver exceptional performance and durability.As the automotive industry moves towards more sustainable and eco-friendly solutions, efficient fuel monitoring becomes increasingly vital. The Auto Gauge Fuel Gauge by [Company Name] is at the forefront of this shift, providing drivers with the necessary tools to manage their fuel consumption and contribute to a greener future.With its innovative features, user-friendly interface, and compatibility with a wide range of vehicles, the Auto Gauge Fuel Gauge is set to redefine fuel monitoring and revolutionize the driving experience. Whether it's for personal vehicles or fleet management, the Auto Gauge Fuel Gauge promises to be an indispensable tool for anyone looking to manage fuel consumption more effectively.About [Company Name]:[Company Name] is a leading manufacturer of automotive parts and components. With a strong focus on innovation and quality, [Company Name] has cemented its position as an industry leader, continually pushing the boundaries of automotive technology. From fuel gauges to engine components, [Company Name] strives to develop products that enhance efficiency, performance, and reliability for both drivers and fleet management companies.

Top Flat Knitting Machine Manufacturer & Supplier in China

Flat Knitting Machine: The Backbone of China Woolen Sweater Knitting IndustryChina has remained one of the largest textile producers globally, with woolen sweater knitting being one of the fastest-growing industries. As the demand for woolen sweaters surges both locally and globally, there has been a consequential rise in the production of flat knitting machines in China. Flat knitting machine, which is used to produce woolen sweaters, has become the backbone of the knitting industry in China.This article provides insights into flat knitting machines, their importance to the China woolen sweater industry, and how they have contributed to the growth of the industry.What is a flat knitting machine?The flat knitting machine uses an automated technique that produces knitted fabrics with intricate patterns. It operates through a system of needles and yarn carriers, which move back and forth horizontally across a flat needle bed. The needle bed has a series of needles arranged in a straight line and embedded in a grooved metal or plastic bed.The flat knitting machine has several variations, such as the fully fashioned machine, the double-bed machine, and the single-bed machine. The fully fashioned machine is designed for knitting shaped garments, while the double-bed machine knits two fabrics simultaneously to create a more robust and intricate fabric. On the other hand, the single-bed machine produces knitted fabrics with a maximum width of 60 inches.The Importance of Flat Knitting Machine to China Woolen Sweater Knitting IndustryChina is renowned for its woolen sweater knitting industry, with the country being the largest wool consumer globally. The industry is driven by a massive demand for woolen sweaters, mainly from North America, Europe, and Asia. The use of flat knitting machines has significantly contributed to the growth of the woolen sweater industry in China in several ways:Increased Speed and Efficiency in ProductionFlat knitting machines have automated the woolen sweater manufacturing process, leading to improved efficiency and speed in production. The machines can produce knitted fabrics at a fast rate, with a single machine knitting up to 500 stitches per minute. This has reduced the production time, and manufacturers can produce large volumes of high-quality woolen sweaters in a short period.High-Quality FabricsFlat knitting machines have played a crucial role in ensuring high-quality fabrics in woolen sweater production. The machines are more efficient in producing intricate patterns and designs, leading to an increase in the quality of woolen sweaters produced. This has attracted more clients globally, who appreciate the unique patterns that the machines generate.Cost ReductionWith the use of flat knitting machines, the cost of woolen sweater production has reduced significantly. The machines operate with a low error rate, reducing losses in the production process. The automation of the woolen sweater production process has also led to a reduction in labor costs, further reducing the cost of production.ConclusionThe production of woolen sweaters is a vital industry in China, driven by the demand for high-quality woolen sweaters globally. The flat knitting machine has revolutionized the woolen sweater manufacturing process, leading to increased efficiency, high-quality fabrics, and cost reduction. As the demand for woolen sweaters continues to surge globally, the use of flat knitting machines will continue to be crucial in meeting the demand and sustaining the growth of the woolen sweater knitting industry in China.

Efficient Selector Solenoid: A Game-Changer in Modern Technology

Title: Innovative Selector Solenoid Revolutionizes Industrial AutomationIntroduction:In today's rapidly advancing industrial automation landscape, one company is leading the charge with its groundbreaking technology and expertise. This company, which specializes in the design and development of high-quality industrial components, has recently unveiled its latest marvel - the cutting-edge Selector Solenoid.Selector Solenoid: Redefining Efficiency and Precision in Industrial AutomationThe Selector Solenoid, developed by this renowned company, is set to revolutionize the field of industrial automation. With its innovative design and advanced features, this high-performance solenoid offers unparalleled efficiency, precision, and reliability, setting a new standard for the industry.Efficiency and Power Optimization:The Selector Solenoid is engineered to enhance efficiency and minimize energy consumption in industrial processes. By employing smart power optimization algorithms, it ensures optimal power usage, significantly reducing overall operating costs. This feature makes it an ideal solution for high-volume applications, such as assembly lines, production plants, and logistics facilities.Advanced Actuation Technology:Equipped with advanced actuation technology, the Selector Solenoid achieves lightning-fast response times, enabling rapid and precise movements. This technology allows for seamless integration into complex automated systems, improving overall productivity and operating efficiency. Furthermore, the solenoid's robust construction ensures a long lifespan and minimal maintenance requirements, making it a cost-effective choice for industries of all scales.Flexibility and Customizability:Recognizing the diverse needs of different industries, the Selector Solenoid offers versatile customization options. Companies can tailor the solenoid's specifications, such as voltage, force, and stroke length, to their specific requirements. This flexibility ensures that the solenoid seamlessly integrates into existing infrastructure while delivering optimal performance.Reliability and Safety Assurance:The Selector Solenoid prioritizes reliability and safety by incorporating fail-safe mechanisms and stringent quality control processes. Its design includes built-in protections against overheating and voltage fluctuations, ensuring consistent performance even under demanding conditions. The solenoid's compliance with industry safety standards guarantees the well-being of operators and minimizes the risk of accidents.Industry Applications:With its exceptional design and performance, the Selector Solenoid finds applications across various industries. In the automotive sector, it enables precise control of assembly line mechanisms, contributing to improved production quality and efficiency. In warehousing and logistics, the solenoid facilitates the smooth operation of material handling and sorting systems, reducing errors and optimizing throughput.Furthermore, the Selector Solenoid proves invaluable in the pharmaceutical and medical sectors, where it contributes to the precise movement and positioning of delicate instruments in laboratory automation and medical diagnostics equipment. In these industries, the solenoid's reliability and precision are critical to ensuring accurate results and maintaining quality standards.Partnerships and Collaborations:To amplify the reach and impact of their groundbreaking Selector Solenoid, this company has strategically forged partnerships with industry-leading automation manufacturers and integrators. By fostering collaboration with these key players, the company aims to streamline the adoption and integration of their solenoid into a myriad of automation solutions, accelerating technological advancements in industrial automation.Conclusion:In the progressive world of industrial automation, the selector solenoid developed by this visionary company stands out as a game-changer. Its exceptional efficiency, precision, reliability, and customization options ensure seamless integration into diverse automation systems, benefiting industries across the board.By harnessing the power of the Selector Solenoid, industries can unlock unparalleled productivity gains and operational excellence. With an unwavering commitment to innovation and customer-centric solutions, this company continues to shape the future of industrial automation, paving the way for a more efficient and advanced industrial landscape.

How to Modify Your BMW 530i Bumpers to Look Like an M5

article about how BMW owners are customizing their cars.BMW Owners Find Ways to Customize Their Cars BMW owners have always been known for taking pride in their vehicles and finding ways to make them stand out from the crowd. One popular way that owners are customizing their cars is by modifying their front and rear bumpers to the M-5 style.Recently, a forum post on BimmerFest BMW Forum has been buzzing with discussion about how to modify the stock 530i front and rear bumpers to look like the M-5 style. One BMW owner shared his experience of converting his stock 2003 530i bumpers to M-Technic Aero.The post, which has received thousands of views and comments, has sparked a conversation about the different ways BMW owners are customizing their cars. Some BMW enthusiasts are sticking to traditional modifications while others are getting creative and pushing the limits with their customizations.From custom paint jobs to performance upgrades, BMW owners are always testing the boundaries and adding personal touches to their vehicles. Customizing the bumper is a popular customization because it gives the car a sportier and more aggressive look. The M-5 style is especially popular among BMW enthusiasts because of the way it emphasizes the car's curves and angles.However, there are potential issues that come with modifying the bumper. As the forum post mentions, it's not an easy process and can result in some remaining issues. Customization requires careful selection of components, testing and modification for perfect installation. Additional work may be necessary to properly mount the bumper for following the new design.It's important to keep in mind that any modification to a BMW vehicle will have an impact on the car's performance and resale value. Often modifications are done to personalize the appearance regardless of the cost and risk of damage and overall loss of resale value.Aside from bumpers, BMW owners are also customizing their vehicles with different wheels, suspension, and exhaust systems. The possibilities are endless, and it shows BMW owners' passion for their vehicles.In conclusion, BMW owners are finding innovative ways to customize their vehicles, making them unique and personalized. While modifying the bumper to the M-5 style is a popular customization, it's important to consider the potential risks and costs associated with it. Regardless, BMW owners' constant desire for customization will continue to make the brand popular among enthusiasts.

Revolutionary cam structure enhances electronic Jacquard machine functionality

Innovation is the cornerstone of progress in any industry, and the textile industry is no exception. Companies that manufacture weaving machines have been working tirelessly to develop new technologies that can improve weaving efficiency, accuracy, and creativity.One of the most innovative weaving technologies currently available is the electronic jacquard machine with cam structure. This machine is a breakthrough in weaving technology that combines the best aspects of traditional jacquard machines with modern electronic control systems, improving efficiency and reliability in the weaving process.The electronic jacquard machine with cam structure is unique in that it integrates the mechanical cam structure with electronic control for setting the pattern. With this technology, the weaving process is not only faster and more efficient, but also a lot more precise.One leading manufacturer of the electronic jacquard machine with cam structure is a Chinese-based company. Located in Shenzhen, the company has carved a niche for itself in the weaving machine industry. With years of experience and a keen focus on research and development, the company has developed one of the most advanced electronic jacquard machines in the market.The company’s electronic jacquard machine with cam structure has gained wide acceptance in the textile industry around the world, thanks to its impressive features. With it, textile manufacturers are able to produce high-quality fabrics that feature intricate designs, vibrant colors, and a superior finish.Some of the features of this electronic jacquard machine that have made it popular among textile manufacturers include the ability to work with a wide range of fabric types and weights, ranging from light to heavy fabrics. The machine is also capable of producing fabrics with a maximum width of 380cm, making it ideal for large-scale industrial production.The company’s electronic jacquard machine with cam structure is equipped with advanced software that controls the weaving process, offering users the ability to design intricate patterns that cannot be created by conventional weaving machines. This enables textile manufacturers to produce unique and customized fabrics, increasing their competitiveness in the industry.One of the most impressive advantages of the electronic jacquard machine with cam structure is the speed of production. The machine is capable of producing large quantities of fabrics in a short period of time, significantly reducing production time, and cutting down operational costs for textile manufacturers.Thanks to the machine’s electronic control system, the weaving process is highly automated, minimizing the need for human intervention, and reducing the likelihood of errors in the weaving process. This not only makes the machine highly efficient but also significantly reduces the need for maintenance and repair.The company’s electronic jacquard machine with cam structure has been used in the production of fabrics for a wide range of textile applications, including home textiles, fashion, automotive, and medical textiles. Its high precision and accuracy in the weaving process have made it a popular choice for creating fabrics that require a high level of detail, such as upholstery fabrics, drapes, and curtains.In conclusion, the electronic jacquard machine with cam structure is a breakthrough in weaving technology that has revolutionized the textile industry. The machine’s advanced features, including the integration of mechanical cam structure with electronic control, high precision, and speed of production, have made it a popular choice for manufacturers around the world. With the electronic jacquard machine with cam structure, textile manufacturers can produce high-quality fabrics with intricate designs, vibrant colors, and a superior finish, positioning them to remain competitive in the global market.